Cold Frame Temperature Control for April

Author: Gregory Doran

Published: 25th August 2021

Problem

We have a cold frame at home, which is mostly used in early spring to provide warmth to germinating plants. It provides both protection from wind and cold but all too often on a sunny day it will overheat. This in turn risks damaging the plants within it as temperatures ending up ranging from 1 to 45 degrees celsius (34-113 Fahrenheit).

When looking at how to resolve this particular problem the most obvious one is to open and close the lid in order to regulate the temperature of the air within the frame. Initially I wanted to design something electronic which could monitor humidity as well as temperature and along with a motor could lift the lid. The plan was to do this until someone older and wiser told me that there is a solution that already exists.

A common solution used on greenhouses, including commercial ones, is a mechanical approach combining some material (typically wax) that expands under heat in a cylinder attached to a leaver. You can find a lot of these available online.

This is the Bayliss Greenhouse Autovent, which unfortunately is only designed to fit a greenhouse. Even if it would fit my cold frame it would require me to screw it into the lid preventing the door from being opened and closed.

Requirements

- Opens the lid sufficiently that it cools the inside when it's getting too warm.

- Unlike existing solutions for greenhouses it would need to allow me to continue to open and close the lid manually.

- Be as cheap as possible.

- Not involve any electronic components as I originally intended. It would be mechanical in the same way that greenhouse solutions work.

Temperature reading showing high maximum and low minimum in spring

Design

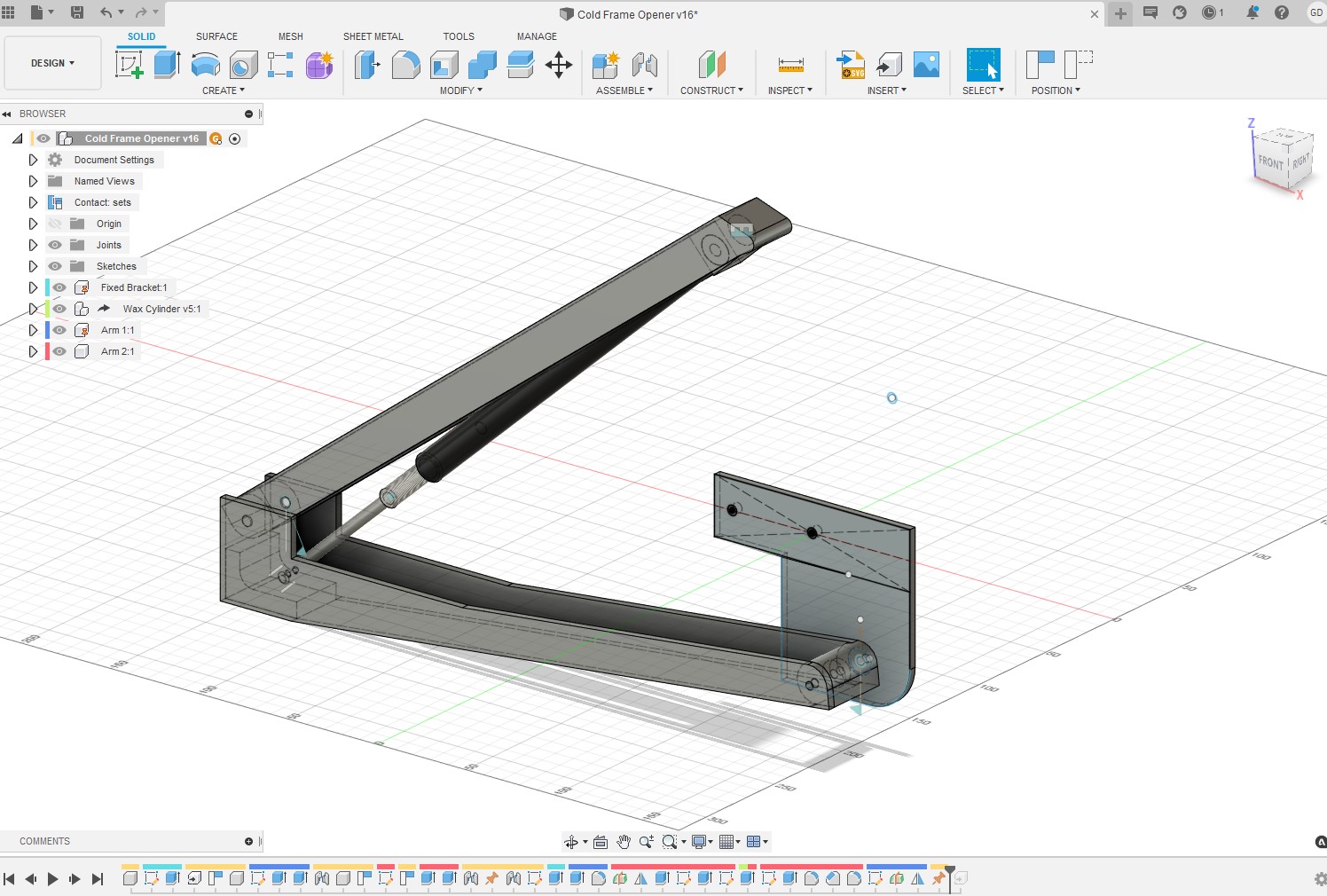

Having abandoned an electronic approach and with it being mid-spring the urgency of this increased. Knowing that spare wax cylinders for the greenhouse arms are available on Amazon for £12 initially I was attempting to adapt the exising design of those to suit the cold frame. These are composed of two arms and fixings at both end. The wax cylinder has a lever which then extends when in direct sunlight and contracts, with some pressure applied, for example with a spring. This separates the two arms lifting the windows in the Greenhouse.

Having spent quite a lot of time in Fusion 360 trying to replicate this I quickly realised that this wasn't necessary in my case. However, the time was spent well learning about collision and joints in Fusion 360.

First design with two arms (abandoned)

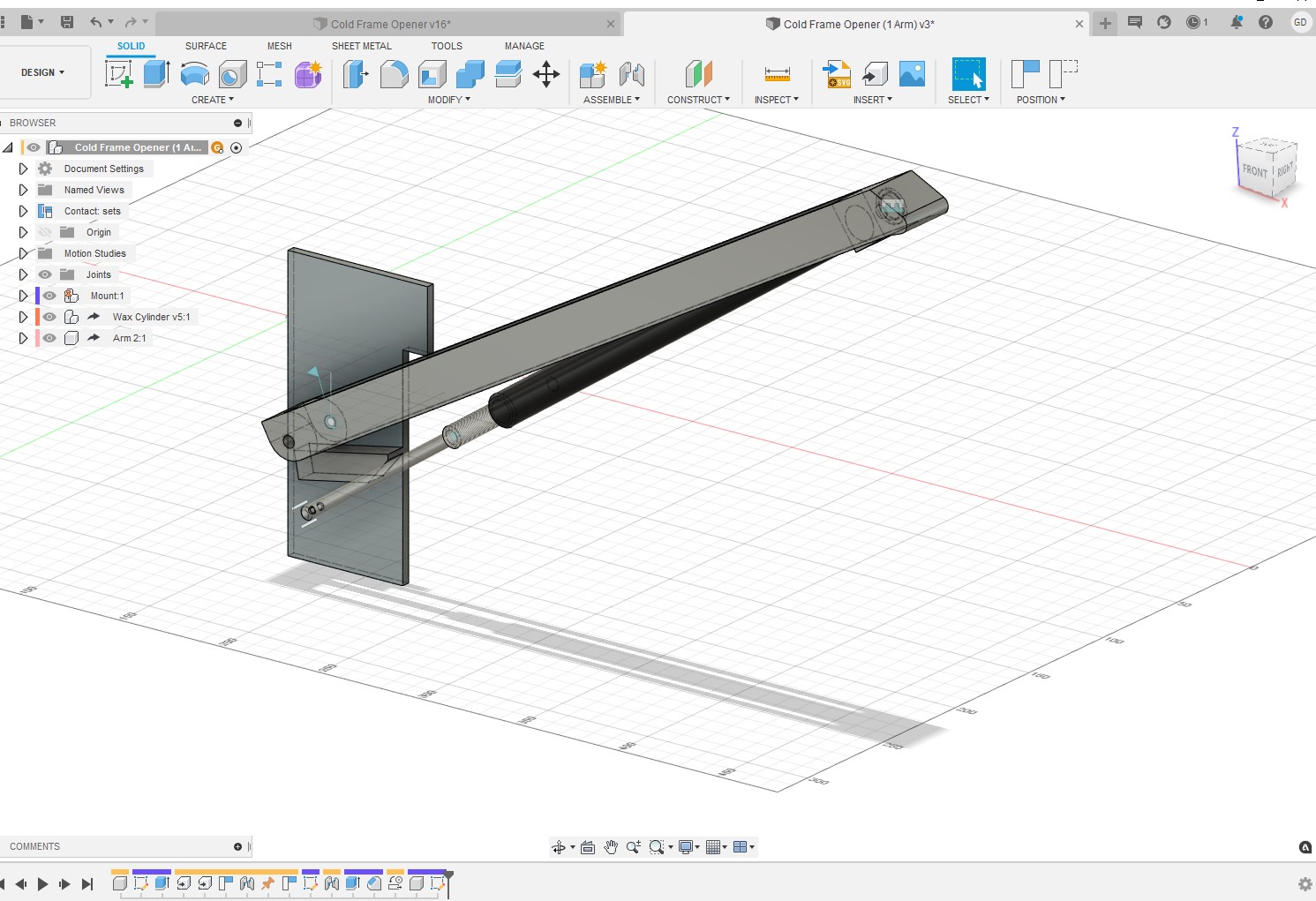

Second design with one arm but fixing to push off (also abandoned)

Solution

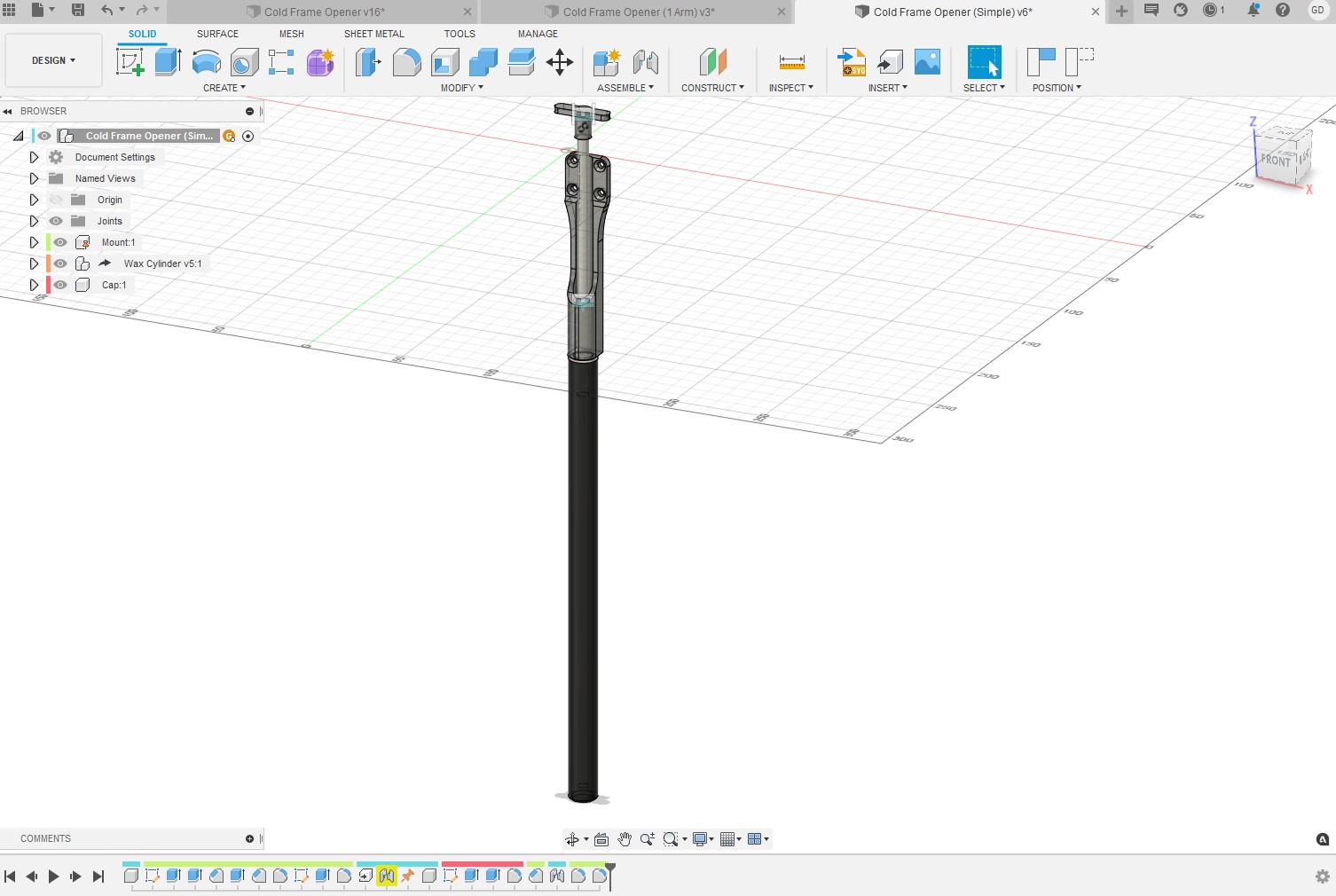

Having spent some time looking at the two-armed and one-armed approach the chosen solution had no arms at all!

The final design

This design has two parts:

- A fixing that the cylinder can be hand screwed into, as this example had threading. It can then be screwed into the wood of the cold frame at a suitable distance from the hinge with a couple of short wood screws.

- A cap on the end of the lever which distributes the force on the surface of the lid.

This design assumes that the lid is weighted as the cylinder will not retract unless some force is applied. In the case of green houses that comes from a spring, for this it relies on the weight of the lid.

Happy plants! Marigolds, tomatoes, multi-sown beetroots, cabbages, peppers and turnips.

Conclusions

The simple design has worked really well for me. My cold frame is south facing so when the sun does come out it's providing direct sunlight to the wax cylinder so it reliably opens in hot sunny weather and closes in the evening. It does peak quite high sometimes but presumably cools as it does open - it would be really nice to have the temperature and humidity monitored as a time-series at some point.

Having given one of these to someone else they have reported not so much success. Their cold-frame is north facing and somewhat shaded. The only conclusion from that is that it won't operate as well without direct sunlight and that the wax will not expand from just warmth alone but requiring also the sun's rays on the black painted cylinder, which in my case is well exposed.

With this project simpler is better. I am glad to have abandoned my previous ideas. Always start with something simple!

With that in mind, the existing solutions had influenced my design. They shouldn't have really other than providing the direction towards the use of the wax cylinder.

Bill of Material and STLs

If you want to build one of these yourself you'll need:

- 3D printed parts (I used PET - ABS would work well I guess but PLA would probably wear from UV). STLs available here .

- The wax cylinder. I bought this one on Amazon .

- 4 x short wood screws and a screwdriver.